I am always looking at what’s around us. Materials, technologies, product, trends, culture, science, phenomenon – everything. I never stop. Erm… never. This constant observation helps me to shape ideas, cross-pollinate and see into a future.

Below is the work of other designers which caught my eye:

011_flax_chair

A beautiful

010_tiny_formed_key_flick

Simplicity speaks louder than words.

009_squeezable_metal_bottle

The KEEGO team have created the world’s first squeezable Titanium bottle. Support the kickstarter campaign and help these guys commercialise some genuine product innovation. Cannot wait to get my hands on one.

008_trusco

TRUSCO: Elegant, durable, and functional. The refined solution is result of embracing the manufacturing methods which then become the strong design language. Japanese design, coveted by ‘designers’, and a reliable staple for others.

007_falling_forward

The Nike Zoom Vaporfly Elite: An extreme 30mm heel of super EVA and engineered carbon fibre blade aim to assist unlocking the 2hr Marathon. Hmmm.

006_tex_lock

After trawling ISPO 2017 for genuine innovation back in February, I stumbled across this gem: The Tex Lock. Different to most bike security locking chains and wires – this device uses an ingenious collection of materials woven and layered up to create a lightweight cut-resistant rope. At 350g/m this security system is perfect for riders, locking their bikes up for a couple of hours in medium risk areas. A steel lock in comparison is more rigid, almost 3 times the weight and more cumbersome to transport and lock-up.

005_molded_sails

A friend recently explained how Molded Sails are made after working with and visiting the North Sails factory. As the name suggests, these huge sails are laid up in one piece over an electronically adjustable mold bed. This mold has been designed to form the correct volume for the optimum performance. Eliminating the need for conventional sewn seams removes vulnerable stress points and leaves a perfectly seamless curved volume which delivers better airflow. The specific high-strength and low-stretch fibres (Dyneema, Kevlar or Carbon Fiber) are orientated across the sail in the molding process to give the optimum strength across the volume. All the machinery to lay up the sail is controlled by data from a CAD file produced by the sail design engineer. The final process uses robotic heaters and a giant vacuum bag to apply pressure and cure the sail to it’s fixed curved form. This sail will ever be flat!

004_g10

Elegant, utilitarian craftsmanship. Folsom knife, by JAMES.

The handle is made from G10. This material is regularly used on gun handles. A steel mold is heated and forced onto a glass-cloth layup which is coated in Epoxy resin. Once cured the rough form can be machined, sanded and finished to form a totally durable and water-impervious solid. The material is non-conductive, and does not expand or contract with heat change. This results in a very stable solid capable of upholding tight tolerances, that is sure to last the test of time.

003_boosted

Last Mile Vehicle is a term coming to the surface. Boosted boards have a standard range of around 6 miles, add the extended battery and you get 12. So hang on a minute – this just became a really feasible way for people to travel these smaller distances without getting bogged down in public transport? The electric motor and battery spec has improved over the years and boosted now offer some awesome performance, including speeds of 22mph, regenerative breaking and being able to ascend hills of 25% gradient! The electric board scene has been around in the states for a while, how long before we get some electric board buzz in the UK?

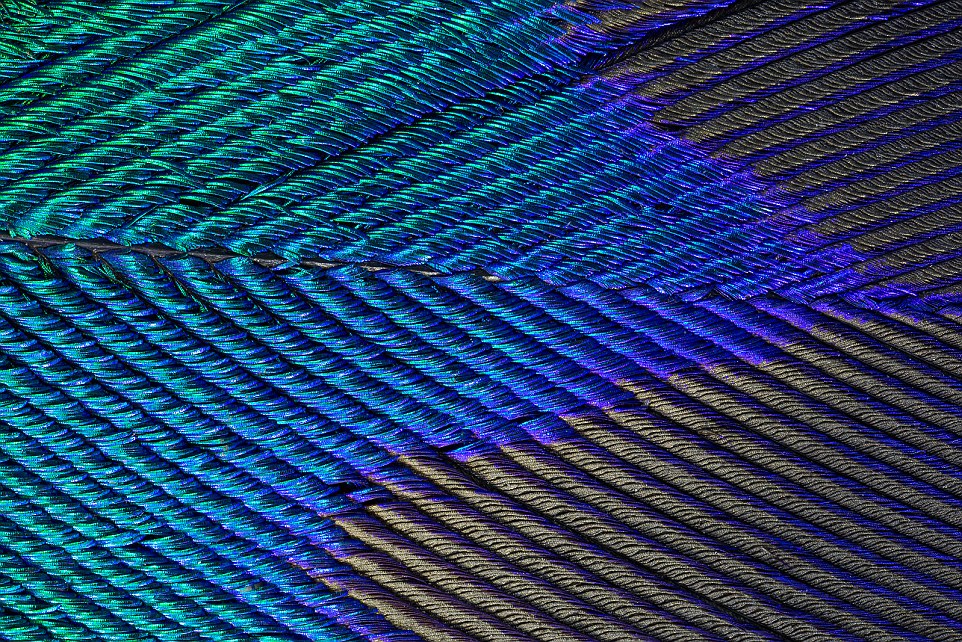

002_iridescence

Photographic study by Neil Waldo. Images at 500X magnification.

Photographic study by Neil Waldo. Images at 500X magnification.

Iridescence is the apparent changing of colour a surface exhibits when the angle at which light hits it is altered. This can be caused by the surface changing formation on a microscopic level or by the viewer moving their viewing position.

So – make a thing, with loads of tiny (really tiny) coloured segments. Those coloured segments should progressively transition from one colour to the next. Then, make the surface flexible. Then flex it. The colour should appear to gradually shift as the surface moves.

The Nike X Stone Island collaboration uses a trilobate (tri-star,) yarn profile lamination on the exterior. This creates variance in the physical structure and alters the opacity to the main fabric beneath. This combined effect delivers a majestic iridescent or metallic sheen as the fabric flexes.

001_flight

It’s time to fly onwards!